Instrumentation components

Since inception, SARASIN ACTOR has developped its own range of instrumentation components to meet specific needs.

These products are designed, assembled and tested at our workshop, then mounted on our control panels or boxes. They can be installed on a wide range of other applications. Feel free to contact us if needed.

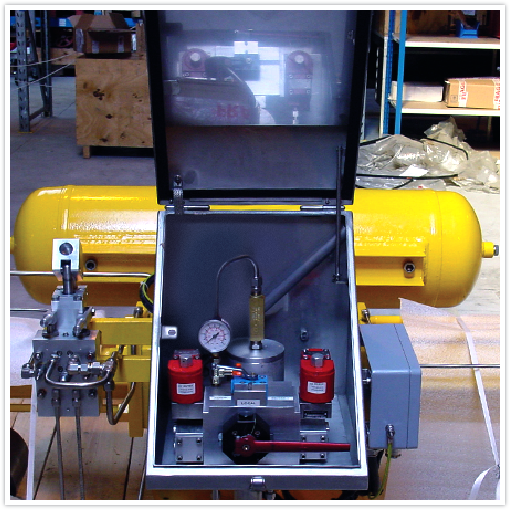

Partial Stroke System

To meet the increasing requirements in terms of reliability and safety of installations, SARASIN ACTOR has developed a modular and innovative system of Partial Stroke Test. This system is adaptable to most existing units and the integration of our controller is achievable by our team in one single day.

Whether on hazardous or safe sites, for 1/4 turn or linear actuators, on SARASIN ACTOR equipments or other, this new feature helps ensure the stroke of your valve when you need it.

Non-exhaustive list of SARASIN ACTOR components

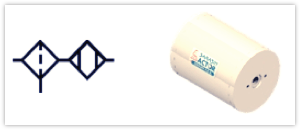

High Pressure Filter / Gas Dehydrator

Filtration 25µm, SS316 made

Manual drain

Light alloy housing (SS316 made on request)

Design pressure: 100 bar (other on request)

Temperature of use: -20°C to +80°C

Maintenance recommendation: once a year

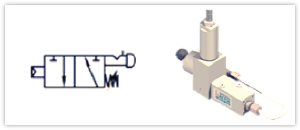

Shutdown Valve

Pressure increasing or pressure decreasing

Light alloy housing

Nitrile / PTFE sealing

Temperature of use: -20°C to +80°C

Maintenance recommendation for safety element: once a year / functional test each 6 months

3/2 high flow piloted valve

10mm orifice size

Light alloy housing (SS316 made on request)

Design pressure: 100 bar

Minimum pilot pressure: 25 bar

Temperature of use: -20°C to +80°C

Maintenance recommendation: each two years

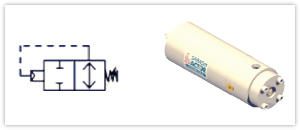

Torque Limitor

Nitrile / PTFE sealing

Light alloy housing

Design pressure: 100 bar

Temperature of use: -20°C to +80°C

Maintenance recommendation for safety element: once a year / functional test each 6 months

Hydraulic Hand Pump

Double Acting design

Light alloy housing

Design pressure: 100 bar

Temperature of use: -20°C to +80°C

Available for Gas-Over-Oil or Direct Gas application

Maintenance recommendation: each three years / functional test each 6 months

Examples of recent projects

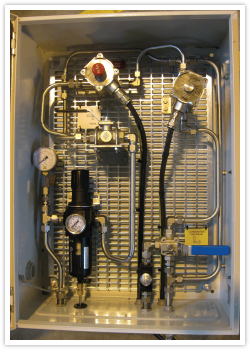

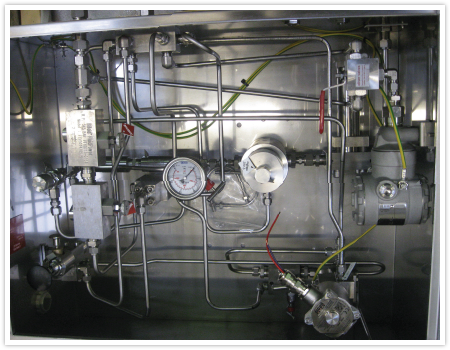

COFFRET Basse Pression - Low pressure control box

COFFRET Haute Pression Gaz Naturel - High pressure natural gas control box

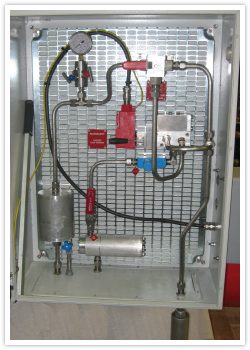

COFFRET Haute Pression Gaz Naturel - High pressure natural gas control box2

COFFRET Haute Pression Gaz Naturel - High pressure natural gas control box3

COFFRET inox - Haute pression hydraulique - Hydraulic control box

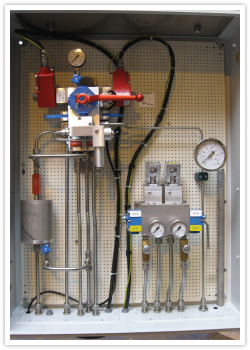

COFFRET inox Basse Pression - Low pressure SS316 painted control box

COFFRET inox Basse Pression - Low pressure SS316 painted control box2

PLATINE inox Basse Pression - gros débit - High flow control panel